It is a simple job but most places don't like do8ng one off's. I was thinking of burners...

Metal Working! Fitting, Machining, Welding, Sheet and General Metal Fab

- Thread starter Urban DH

- Start date

Flow-Rider

Burner

That's a bugger.Thanks for the possible lead on a crown race, unfortunately, the OD of the steerer isn't something a standard 1.5 crown race would fit.

I should have rung the shop and asked them to get their verniers out and measure the crown race.

wasted a couple of hours getting out to the sticks and back. should have got it posted.

However shit my verniers are, they were probably close to 38.1mm for the OD of the fork steerer. The 39.7 ~39.8mm ID of the FSA crown race was never going to fit. we could both see that it was loose on the steerer.

The shop mechanic tried to be helpful, but I had already dealt with the distro, who also tried to be helpful but couldn't find me a crown race to fit a weird steerer diam.

IS there someone in Melbourne (or interstate) who could turn me up a shim or a crown race that would fit, and work with the standard FSA integrated tapered headset I bought? the top parts fit fine, inc top bearing, and the bottom bearing seems to fit fine.

So the bike shop had the standard bearing crown, not the one they claimed for the 38.1 steer?

FSA usually makes most of the OEM headset parts if any would have it, I would suspect it would be in that brand.

Most machine shops would charge a couple of hundred minimum unless they'll do a cash-in-hand job after hours.

oldcorollas

Levin the moment

have you scanned the QR code?Dear Rotorburn Lathe experts:

Some of you may have seen my WTB thread, needing an odd sized crown race, to fit the tapered steerer on an Avanti carbon fibre road fork.

The OD of the base of the fork steerer comes in at 38.06mm, and the ID of the crown race for the tapered integrated headset measures 39.99mm, according to my cheapy micrometer. The metal collar (?) at the base of the steerer is approx 7mm high.

I need someone to turn up a shim to fit over the tapered steerer so that the crown race fits snugly, and I can get on with my build.

It could be Aluminium or Stainless steel. whatever would work best. Is this feasible? how much would it cost? for one or maybe two, because stuff happens...

Thanks in advance, for your consideration.

If it's in greater Melbourne, I can bring the fork to you, and it can be measured with your (no doubt) way better quality micrometer.

Some photos of the offending areas:

View attachment 405813View attachment 405814View attachment 405815View attachment 405816View attachment 405817View attachment 405818View attachment 405819View attachment 405820View attachment 405821View attachment 405822

is this the bit missing? (from a cadent fork on Ebay) if it is.. $100..

Last edited:

ForkinGreat

Knows his Brassica oleracea

Thankyou for the link. I'm a bit sketchy about that fork. Looks Like it's had a rough life. Still no guarantee it will fit. At $50ish, I would take a punt and buy it for the crown race, and toss the fork.

I did show the QR code to the Avanti Distributor. The upshot was that it was old and they didn't have anything that would work for it, or words to that effect.

I've downloaded about 4 QR reader apps and none of them register that as a qr code.

I had a thought to buy a couple of crown race reducers (1.5 to 1 1/8th) and sand down the inside until it fits. would it be better with a split version or an unsplit race?

If that doesn't work, I'm inclined to get Consumer Affairs involved to help get a refund for the frame from the dodgy sellers, as I will be able to show that I have made more than reasonable efforts to get the @$%$#$%# thing in a functional state that's fit for purpose.

I did show the QR code to the Avanti Distributor. The upshot was that it was old and they didn't have anything that would work for it, or words to that effect.

I've downloaded about 4 QR reader apps and none of them register that as a qr code.

I had a thought to buy a couple of crown race reducers (1.5 to 1 1/8th) and sand down the inside until it fits. would it be better with a split version or an unsplit race?

If that doesn't work, I'm inclined to get Consumer Affairs involved to help get a refund for the frame from the dodgy sellers, as I will be able to show that I have made more than reasonable efforts to get the @$%$#$%# thing in a functional state that's fit for purpose.

Last edited:

oldcorollas

Levin the moment

oh, it's a sketchy fork, but is a Cadent with an adapter lookin thing on it

don't think it would matter if split or not functionally

Split, you mainly rely on the radius difference = thickness of the adapter (and it can be slightly bigger or smaller diameer.. but still needs to be close

unsplit, the diameters themselves need to be correct.

JB weld? wire wrap?

wire wrap?  (dodgy as fk)

(dodgy as fk)

don't think it would matter if split or not functionally

Split, you mainly rely on the radius difference = thickness of the adapter (and it can be slightly bigger or smaller diameer.. but still needs to be close

unsplit, the diameters themselves need to be correct.

JB weld?

ForkinGreat

Knows his Brassica oleracea

Unfortunately, they probably just copy/pasted the lines from where-ever. Pretty sure they weren't the page copy from the FSA site.That's a bugger.

So the bike shop had the standard bearing crown, not the one they claimed for the 38.1 steer?

FSA usually makes most of the OEM headset parts if any would have it, I would suspect it would be in that brand.

Most machine shops would charge a couple of hundred minimum unless they'll do a cash-in-hand job after hours.

They were a bit fucking clueless, and the Mechanic at Berwick cycles got a bit bunched up when I pointed out that their own product info was wrong, and that I had already contacted the Distro, and some other pointless action they suggested.

And I was out of fucks to give. I was reminded of that Parks & Rec character Ron Swanson.

"I know More than You" would have been a perfect thing to say at that point.

I think they sensed my thinly veiled contempt. The kicker was to suggest going to a bikeshop "up the road" at about 5 minutes before they were due to close, (hallam cycles), which was super handy, as I didn't know the area, was busting for a piss, and figured I wouldn't make it in time anyway.

Google maps confirms. Ivanhoe cycles Hallam is a good 7-10min away, and that's on a saturday afternoon, not peak cray cray on a friday around 5pm.

Last edited:

ForkinGreat

Knows his Brassica oleracea

I doubt FSA make one any more. I think it's our old favourite, Quickly obsolete proprietary "standards".That's a bugger.

So the bike shop had the standard bearing crown, not the one they claimed for the 38.1 steer?

FSA usually makes most of the OEM headset parts if any would have it, I would suspect it would be in that brand.

Most machine shops would charge a couple of hundred minimum unless they'll do a cash-in-hand job after hours.

Yeah, If I had to pay $200 minimum for a fucking crown race, I may as well buy a $500 Columbus tapered fork from Hillbrick in Sydney, which will fit the crown race that came with the FSA integrated tapered headset.

beeb

Dr. Beebenson, PhD HA, ST, Offset (hons)

If you want to do it well, buy an un-split reducer and have a machine shop turn the ID out to your desired dimension (ideally take the fork along so you/they can check the fit).I had a thought to buy a couple of crown race reducers (1.5 to 1 1/8th) and sand down the inside until it fits. would it be better with a split version or an unsplit race?

Or if you want to try a hack, buy some Metalset and use it to fill the gap between your 1.5" crown race and the fork (FYI - it'll probably also stick the race on unless you grease the race prior to installing. Beware not wiping away excess before it sets too, this stuff is a bastard to try and file off once it's cured...).

[EDIT] If you do manage to find some crusty old machinist that'll actually talk to you (not just look at you warily and grunt, lol), just remember this phrase that should never be uttered - "I was hoping you could do it now...". That is unless you want to be told to 'go away' but in much less polite terminology.

Last edited:

link1896

Mr Greenfield

Clamping a crown race on the OD in a 3 or 4 jaw chuck, only way so it doesn’t go into orbit the moment the tool tip gets neat is to use a split ring clamp on the OD that then goes into the chuck.If you want to do it well, buy an un-split reducer and have a machine shop turn the ID out to your desired dimension (ideally take the fork along so you/they can check the fit).

Or if you want to try a hack, buy some Metalset and use it to fill the gap between your 1.5" crown race and the fork (FYI - it'll probably also stick the race on unless you grease the race prior to installing. Beware not wiping away excess before it sets too, this stuff is a bastard to try and file off once it's cured...).

[EDIT] If you do manage to find some crusty old machinist that'll actually talk to you (not just look at you warily and grunt, lol), just remember this phrase that should never be uttered - "I was hoping you could do it now...". That is unless you want to be told to 'go away' but in much less polite terminology.If they seem like it's something they might do for you, "When do you reckon you might have a chance to play with it?" might be a safer bet.

ForkinGreat, where is this mini project up to?

ForkinGreat

Knows his Brassica oleracea

I bought a carbon fork from ebay that actually fits a 39 point whatever mm crown race. The stock FSA solid ring crown race looked a bit tight to get onto the fully carbon steerer on the ebay fork, but I have a split one from a Banshee headset that fits well and wont f@#$@@ the carbon up.Clamping a crown race on the OD in a 3 or 4 jaw chuck, only way so it doesn’t go into orbit the moment the tool tip gets neat is to use a split ring clamp on the OD that then goes into the chuck.

ForkinGreat, where is this mini project up to?

I do have a crown race installer tool if I decide to use the solid race, but I get wary of putting potential excess stress on carbon parts.

I also found various sellers of tube stock on ebay, one with 38mm ID, and 40mm OD. has to come from china, but I could cut a steerer collar from it that could be fitted to the Avanti fork & provide me with a spare / backup fork.

Going to start the build this weekend.

Last edited:

ausdb

Being who he is

I picked up another toy for the shed this afternoon, my wife's reaction was a bit like @oldcorollas post here.

Except there was no comeback as she doesn't do fake nails or much stuff like that.

Tomorrow's project is to reassemble it and try to rebend a Thule roof carrier that someone managed to straighten out with a little help from their bike and garage.

Except there was no comeback as she doesn't do fake nails or much stuff like that.

Tomorrow's project is to reassemble it and try to rebend a Thule roof carrier that someone managed to straighten out with a little help from their bike and garage.

Had to turn up some coilover ends for my mate and took the time to machine a joiner piece so I can extend the jack stand that sits under the nose of the camper. Simple cylinder with identical dia at the ends to fit inside the stand and a bigger middle to take the vertical load. Made a rooky mistake that at least wasn't scrap bin material. Machined one end oversize to true it up then flipped it to machine the other end, size the middle and bore part way through. Machined the first spigot to size and set the DRO. Took the live centre out and bored it before flipping it to size the other end. Spun the tool around to square the shoulder with a parting tool and then back to the main tooling. Except when I spun the tool back it wasn't in the same position as the first side! Luckily cut undersized because I just ran to the DRO. What the? Then checked the tool. Oops.

fjohn860

Alice in diaperland

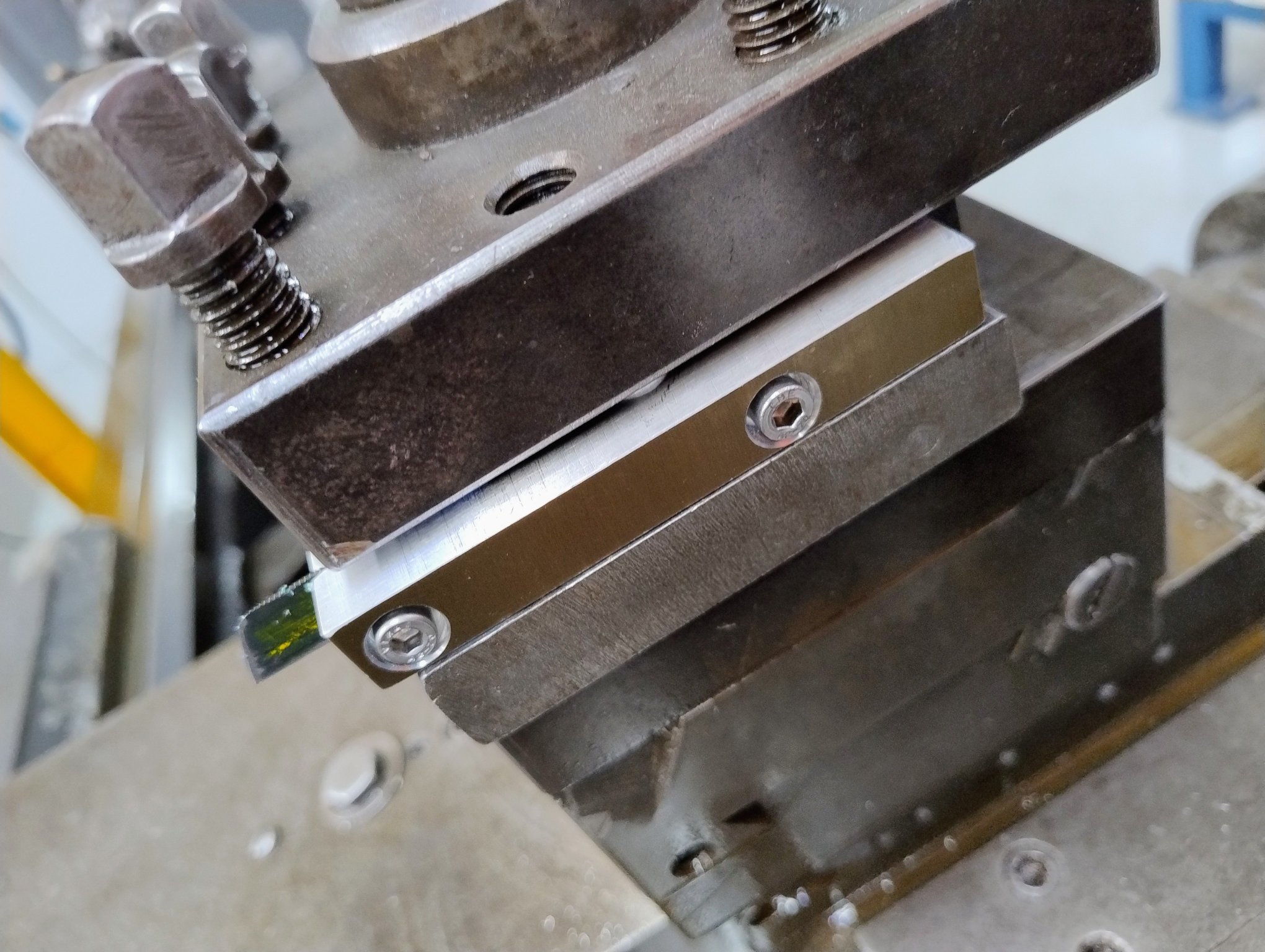

After running out of 3M exterior masking tape yesterday retaping a rim, I decided today that I would make a cutting tool for the lathe to trim the new roll to the correct width.

Last roll I used a stanley knife clamped to the tool post which kind of worked but I felt a trailing cutting edge would work better.

So re-purposed a piece of hacksaw blade and used some aluminium plate I saved from the scrap bin a while ago to come up with this.

Last roll I used a stanley knife clamped to the tool post which kind of worked but I felt a trailing cutting edge would work better.

So re-purposed a piece of hacksaw blade and used some aluminium plate I saved from the scrap bin a while ago to come up with this.

beeb

Dr. Beebenson, PhD HA, ST, Offset (hons)

You're mad, I love it!After running out of 3M exterior masking tape yesterday retaping a rim, I decided today that I would make a cutting tool for the lathe to trim the new roll to the correct width.

Last roll I used a stanley knife clamped to the tool post which kind of worked but I felt a trailing cutting edge would work better.

So re-purposed a piece of hacksaw blade and used some aluminium plate I saved from the scrap bin a while ago to come up with this.

View attachment 406963

View attachment 406962

View attachment 406964

oldcorollas

Levin the moment

that's one sexy shiv!After running out of 3M exterior masking tape yesterday retaping a rim, I decided today that I would make a cutting tool for the lathe to trim the new roll to the correct width.

Last roll I used a stanley knife clamped to the tool post which kind of worked but I felt a trailing cutting edge would work better.

So re-purposed a piece of hacksaw blade and used some aluminium plate I saved from the scrap bin a while ago to come up with this.

View attachment 406963

View attachment 406962

View attachment 406964

fjohn860

Alice in diaperland

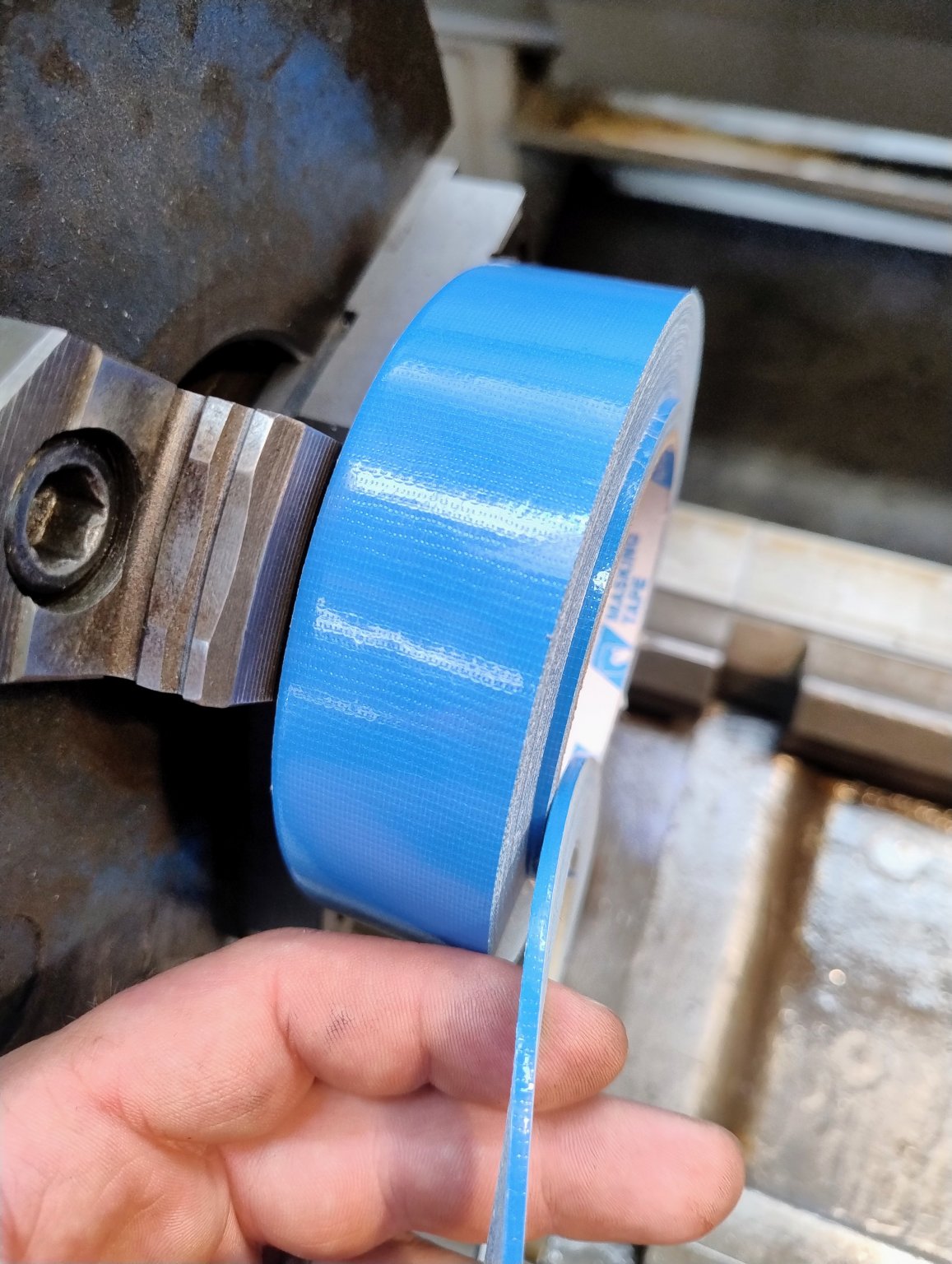

Does work extremely well.... Though not enough length to cut all the way to the cardboard inner, but I didn't want it to deflect when cutting. Not an issue though as I can always cut the rest off as I use the tape. Might still experiment with a slightly longer blade anyway.

Interestingly, the yellow 3M exterior masking tape is no longer on the bunnings shelf just like the scotch blue exterior. This Bear exterior masking tape is much more like a cloth tape than the "ribbed" yellow exterior tape.

Interestingly, the yellow 3M exterior masking tape is no longer on the bunnings shelf just like the scotch blue exterior. This Bear exterior masking tape is much more like a cloth tape than the "ribbed" yellow exterior tape.

beeb

Dr. Beebenson, PhD HA, ST, Offset (hons)

New bear just ain't like the old bear.Does work extremely well.... Though not enough length to cut all the way to the cardboard inner, but I didn't want it to deflect when cutting. Not an issue though as I can always cut the rest off as I use the tape. Might still experiment with a slightly longer blade anyway.

Interestingly, the yellow 3M exterior masking tape is no longer on the bunnings shelf just like the scotch blue exterior. This Bear exterior masking tape is much more like a cloth tape than the "ribbed" yellow exterior tape.

View attachment 406981

View attachment 406982

View attachment 406983View attachment 406984

Blame @bear the bear and his "accept an inferior product" name-slogan.

bear the bear

Is a real bear

New bear just ain't like the old bear.

Blame @bear the bear and his "accept an inferior product" name-slogan.

oldcorollas

Levin the moment

figure to move Fox footnut thread stuff to.. this thread

9mm bit, then M10x1.0 tap, gets ~1 turn on than binds. likely Pitch?

super bodgily ran a 9.5mm bit through the tapped bodgynut, and gets 3 clear turns on then binds tight.. so the ID makes a little difference and not fully restricted by OD, but.. pitch is wrong..

so measure threads...

OD = pretty close to 10.20mm

8 threads = ~8.4mm (+-0.05) = 1.05mm pitch?

24TPI = 1.058, but putting a 24TPI tap against the thread "rocks" a bit and can see 24TPI is slightly coarser...

don't think the damper threads are assymetric, but hard to see..

couldn't find anything that matches here..

or here https://pages.cs.wisc.edu/~bolo/workshop/thread.html

going to try 3D print 1.0 vs 1.05... and maybe tool doesn't even need a thread..

edit: other ppl measuring etc

www.mtbr.com

www.mtbr.com

9mm bit, then M10x1.0 tap, gets ~1 turn on than binds. likely Pitch?

super bodgily ran a 9.5mm bit through the tapped bodgynut, and gets 3 clear turns on then binds tight.. so the ID makes a little difference and not fully restricted by OD, but.. pitch is wrong..

so measure threads...

OD = pretty close to 10.20mm

8 threads = ~8.4mm (+-0.05) = 1.05mm pitch?

24TPI = 1.058, but putting a 24TPI tap against the thread "rocks" a bit and can see 24TPI is slightly coarser...

don't think the damper threads are assymetric, but hard to see..

couldn't find anything that matches here..

or here https://pages.cs.wisc.edu/~bolo/workshop/thread.html

going to try 3D print 1.0 vs 1.05... and maybe tool doesn't even need a thread..

edit: other ppl measuring etc

Fox nut internal thread

Last edited: