The Woodwork thread

- Thread starter ausdb

- Start date

Beautiful grain.

DougalStrachan

Likes Dirt

Good to see my son is already way more talented than me when it comes to hands on work. I remember my high school woodwork being way crappier than this

Anyone following Sampson Boat Co? Some awesome woodworking and boat building.

Teaser from a couple of years or so back.

Teaser from a couple of years or so back.

teK--

Eats Squid

What's the rule of thumb then? Keep lots of bees onboard for in case you have a leak.The woodwork skills of some shippies is next level.

Build a house and 5mm out you won't see it.

Build furniture a couple of mm out and you can hide it.

Build a wooden boat out by a bee's dick and it sinks.

Shed building is a level below house building. BIL built his with a chainsaw and auger.

Last edited:

Bit more progress. I got the pine wrong. It is plum pine (col) or Illawarra plum, podocarpus elatus. I have a few trees because the berries are a bush food.

So rough planks after thicknessing

Then sized (no idea whose boots but they are wet and stink)

Lots of test pieces to set up the dovetail jig

I had never used one of these before and they are quite fickle. Through dovetails would be easier, getting the balance right so the joints are decent but not too tight or loose is tedious. So much so I nearly opted for a plain 1/2" bit and finger joints. Happy I persevered but honestly I wasted 4 hours getting the set up right.

The final joint has just enough space for glue.

Then it was all production line to get the pieces done.

Note the mountain bikes in the background! I discovered though that the jig clamp can move around and that also moves the comb which affects the depth of cut. Hopefully ok. Test fits all seem fine. Have to clean up before gluing and my RO sander is dead. Will make three boxes then glue these together. Plum/camphor/plum. Oh and the camphor was a shit. It was not the best and splintered though the cracks but that is inside so doesn't matter. I was planning biscuits but I had to take the bits down to 1/2" because the camphor didn't clean up. For what it is glue alone will be fine and there will be aluminium tracks inside across the joins.

First time I have taken slabs and dressed them to make something. Bloody good process and it saved some wood that was destined for the fireplace.

So rough planks after thicknessing

Then sized (no idea whose boots but they are wet and stink)

Lots of test pieces to set up the dovetail jig

I had never used one of these before and they are quite fickle. Through dovetails would be easier, getting the balance right so the joints are decent but not too tight or loose is tedious. So much so I nearly opted for a plain 1/2" bit and finger joints. Happy I persevered but honestly I wasted 4 hours getting the set up right.

The final joint has just enough space for glue.

Then it was all production line to get the pieces done.

Note the mountain bikes in the background! I discovered though that the jig clamp can move around and that also moves the comb which affects the depth of cut. Hopefully ok. Test fits all seem fine. Have to clean up before gluing and my RO sander is dead. Will make three boxes then glue these together. Plum/camphor/plum. Oh and the camphor was a shit. It was not the best and splintered though the cracks but that is inside so doesn't matter. I was planning biscuits but I had to take the bits down to 1/2" because the camphor didn't clean up. For what it is glue alone will be fine and there will be aluminium tracks inside across the joins.

First time I have taken slabs and dressed them to make something. Bloody good process and it saved some wood that was destined for the fireplace.

Last edited:

Flow-Rider

Burner

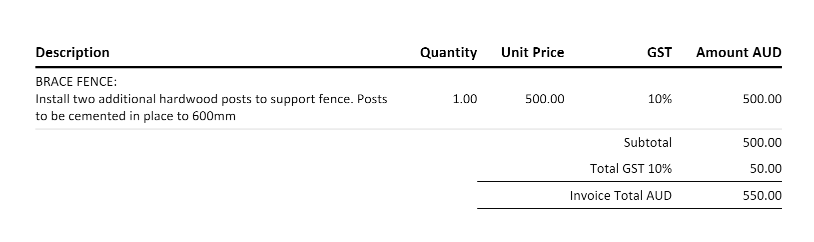

Does this look like a treated pine post to people?

And yes, I'm a fuckwit that tried to save some time and should have done it myself.

And yes, I'm a fuckwit that tried to save some time and should have done it myself.

Last edited:

slowmick

38-39"

That's just shit @Flow-Rider - if they want that sort of money they should do a proper job.

Flow-Rider

Burner

I wish it was a joke but this is what you get these days, the builder that did the fence originally, just suspended that part of the fence under tension from the two other fences on the side, the uprights are sitting on top of the dirt.That's just shit @Flow-Rider - if they want that sort of money they should do a proper job.

teK--

Eats Squid

Was the wood so hard they couldnt notch it?Does this look like a treated pine post to people?

And yes, I'm a fuckwit that tried to save some time and should have done it myself.

View attachment 401316View attachment 401319

View attachment 401317

View attachment 401318

rockmoose

his flabber is totally gastered

Oh, you want the premium package? You pay extra for that.Was the wood so hard they couldnt notch it?

Flow-Rider

Burner

I'm pretty sure the uprights are just cheap-treated soft pine but rough as guts work. I'd say it's lucky if the posts are deeper than a foot in the ground, you can wobble the crap out of them.Was the wood so hard they couldnt notch it?

The funning thing is that I got quoted $250 a meter for a completely new wooden fence, 2 x posts somehow equals $500.Oh, you want the premium package? You pay extra for that.

You can poke your finger in that gap between the fence rail and post.

rockmoose

his flabber is totally gastered

Whaaaat? So, it's not even attached?I'm pretty sure the uprights are just cheap-treated soft pine but rough as guts work. I'd say it's lucky if the posts are deeper than a foot in the ground, you can wobble the crap out of them.

The funning thing is that I got quoted $250 a meter for a completely new wooden fence, 2 x posts somehow equals $500.

You can poke your finger in that gap between the fence rail and post.

View attachment 401328

Fuckin' tradies

indica

Serial flasher

That's not funning at allThe funning thing is that I got quoted $250 a meter for a completely new wooden fence,

Box went together ok but not all that happy with it to be honest. I made a boo boo and didn't check the moisture content of the camphor and I think it was still a bit green. I sized the camphor pieces and left it a few days to make up the box. Then before I joined the box sections together I block sanded the edges to make sure they were straight. The plum barely had any material to be removed but the camphor needed a bit of work. Didn't think about it but now realise that the camphor had warped after rethicknessing. Anyway when it all went together as a box there were gaps between the three pieces and where the dovetail jig moved the dovetails are different. A learning curve of sorts because when we fitted all the band stuff in there it is clear that 1/2" thickness is not enough to take the weight and the abuse it will get. Thus I will finish sand this after a couple of spots of filler and rout a chamfer on the outside edges and the box will get used as a monitor stand in the wife's study. Laptop and other stuff can sit inside. Ah well. Final finish will be just a clear gloss varnish so the timber will look like the pics.

Anyway a few pics of my not so great workmanship. The clamping screws on the jig also had a problem, they are plastic knobs on a steel bolt and the plastic slipped. I temporarily drilled and pinned the knobs but I will machine up some new knobs from ali and roll pin those. And I know now how to set the dovetail jig so that it doesn't move between pieces, the comb will get dowelled to the slide and if I need a spacer I will work out the size and pin that to the guide. The next attempt WILL be betterer.

I am still pleased with how the timber came out from some throwaway slabs. Need to check moisture and also the plum had some fungus that shows up as the blue hue in the timber. Not an issue for this but would be for furniture.

Sigh.

Anyway a few pics of my not so great workmanship. The clamping screws on the jig also had a problem, they are plastic knobs on a steel bolt and the plastic slipped. I temporarily drilled and pinned the knobs but I will machine up some new knobs from ali and roll pin those. And I know now how to set the dovetail jig so that it doesn't move between pieces, the comb will get dowelled to the slide and if I need a spacer I will work out the size and pin that to the guide. The next attempt WILL be betterer.

I am still pleased with how the timber came out from some throwaway slabs. Need to check moisture and also the plum had some fungus that shows up as the blue hue in the timber. Not an issue for this but would be for furniture.

Sigh.

Flow-Rider

Burner

Not on every fence rail, I didn't have time to check but I think the posts aren't leveled.Whaaaat? So, it's not even attached?

Fuckin' tradies