Hit a bit of a snag rebuilding an old Cannondale today - the back shock wasn't holding air at all, so I did a basic air can service on it. Unfortunately after that it still wouldn't take any air, and checking it out a little more it's got a huge leak through the rebound / pro pedal knob.

My gut feeling is that it's stuffed, and since it's ~15 years old throwing money at a damper service seems like a bad idea. I can't find much at all on air leaks from rebound, it seems fairly common to have an oil leak but nothing much past that. There's nothing obviously wrong with the shock head, but there was a mention somewhere on the interwebs of a crack in the metal causing this to happen.

Any ideas? Unfortunately doesn't seem to be much around in used 190/45ish shocks right now so I'm a little stuck with the project at the moment

My gut feeling is that it's stuffed, and since it's ~15 years old throwing money at a damper service seems like a bad idea. I can't find much at all on air leaks from rebound, it seems fairly common to have an oil leak but nothing much past that. There's nothing obviously wrong with the shock head, but there was a mention somewhere on the interwebs of a crack in the metal causing this to happen.

Any ideas? Unfortunately doesn't seem to be much around in used 190/45ish shocks right now so I'm a little stuck with the project at the moment

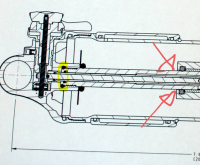

Attachments

-

41.6 KB Views: 98