This journey started in the back half of 2020 when I noticed a couple of cracks had developed in my Trek Farley 9.6 frame, a friend had access to NDT facilities for carbon fibre and concluded that the cracks weren't immediately terminal however they would likely propagate so it was time to get the ball rolling on a replacement frame. First port of call was to contact Trek, no dice on warranty replacement as the little serial number stickers had long fallen off and no chance to purchase a new frame as they weren't bringing the Farley into the country any more not even under special order. A quick Hamboing turned up that Pivot where still doing the LES Fat but availability was scarce and the asking price was starting to nudge custom frame numbers, thus the seed was sown. Back to the old Hambo machine, a few builders had fat bike offerings but something was still gnawing away in the back of my mind, the primary purpose of this bike is for bike packing and back country adventuring thus many a trip had been spent slogging it out across sand dunes, churning through muddy bog holes or wading across waist deep river crossings and then listening to the orchestra of horrible noises that emanated from the encrusted drivetrain and it was always around this point that the discussion turned to "how good would a gearbox be", I decided that if I was going to go custom frame then why not go all in and find out. Roadblock number one, the builders who did fat bikes weren't interested in gearboxes, the builders who did gearboxes weren't interested in fat bikes and the few who would consider both weren't interested in the little details and aesthetics I wanted, it had been near six months since I'd started looking and I was becoming frustrated. Fast forward to February 2021 I scrolled past a post on the socials from one of bike industry photographers I follow showcasing a Ti frame from a brand new Newcastle based bicycle company, I reached out to them and a meeting was set at a local coffee house for the following week.

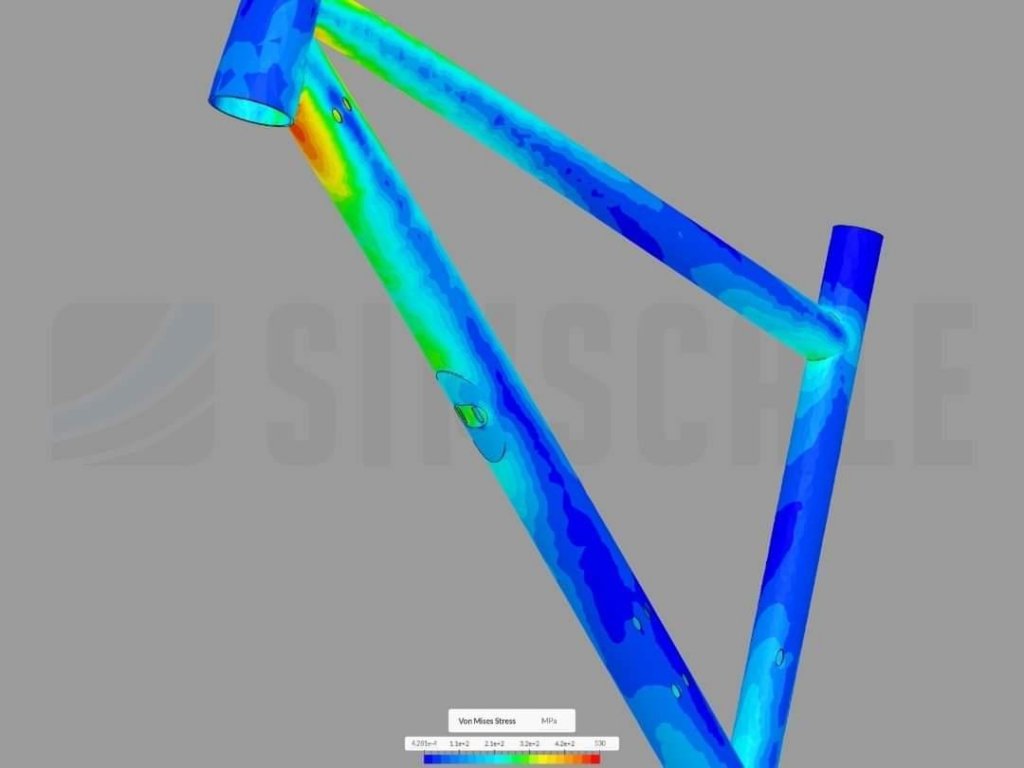

During the first meeting we talked shop for a bit, discussed the design and manufacture process and I had a look at one of the stock frames to get a feel for the quality and workmanship I could expect from the factory. Over the next couple of months we went back and forth with design changes and compromises to accommodate the gearbox into a frame with similar geometry as the outgoing Farley, I also wanted a few extra tweaks to cable management that the factory weren't overly happy with so ended up modelling the front triangle so that I could conduct an FEA analysis and I could convince myself we wouldn't be introducing any additional weaknesses. With all that out of the way the trigger was pulled early April 2021 and an expected delivery date of the end of July was given. Roadblock number two, no surprises here the expected delivery date blew out to the end of October and then to early December but I knew that this was a possibility when I placed the order.

I'd slowly amassed the build kit over this time so I was ready to go when the frame arrived and was personally delivered to my house on a Saturday morning. I spent a lazy weekend building it up, there were a few little hiccups mainly around things I hadn't considered in relation to gearboxes (I spent a good five minutes stressing at one point because I couldn't find the bottom bracket I was sure that I'd ordered *fuckwit) but finally it was finished and all that was left was to bolt on the cranks, drive side on, non-drive side on, give them a quick spin before putting the chain on... aaaand fuck. Non-drive side crank arm fouls on the rear stay... double fuck. Quick sanity check to ensure I hadn't reserved myself a spot in the fuckwits thread and then followed by call, after that we spent about a day back and forth checking measurements and frame alignment, my original concern was that the Pinion bridge had been welded in out of square but it turned out that the rear stay was sticking out too far on that side and a day after that came the response from the factory.

"The bicycle frame itself is very difficult to make. After welding, there was a certain deformation. From the data you give me. This deformation is within tolerance".

From this point on it's important to say that Craig from Rad Bike Co. was amazing to deal with, understandably neither of us were impressed with the response from the factory and their offer to return it for repair with a three month turn around did not fill me with any great level of confidence, to his credit Craig jumped in and started discussions with a local fabricator to make the repairs for which he would still honour the original frame manufactures warranty. By early March the repairs were complete and the frame was back in my hands, unfortunately I was flat out with work and Overland Track preparations and was only just recently able to find time to build it back up again, finished putting it together around 6pm Friday evening and by 8pm I was departing the Awaba carpark up Mt Faulk road to head into the Watagans for a two night 80km shakedown ride. Initial ride report is amazing, nothing appears to have been lost in the geometry translation, the Ti is just as compliant as the old carbon frame and the gearbox handled the less than ideal conditions without missing a beat. I'll need so time to get used to the shifting and also the backlash that is especially prominent in the lower gears but overall absolutely stoked to finally have a bike worthy of a PYR thread.